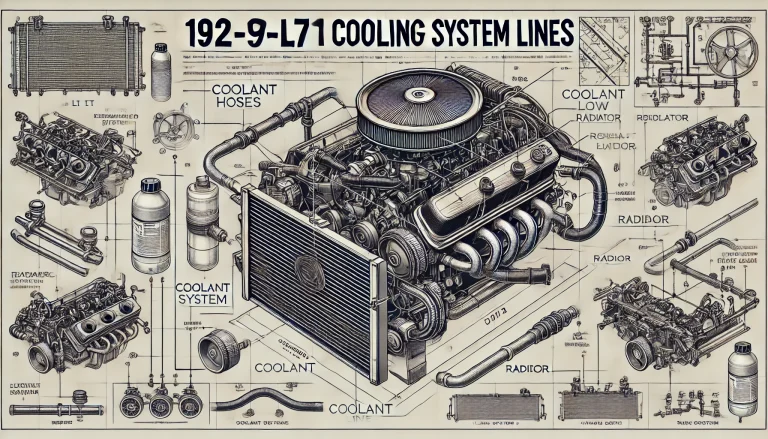

The 192-97 LT1 cooling system lines play a crucial role in regulating engine temperature, ensuring optimal performance and preventing overheating. Designed for durability, these lines help maintain steady coolant flow throughout the engine.

Key Components of the LT1 Cooling System

The LT1 cooling system is designed with several critical components that keep the engine temperature within a safe range. The 192-97 LT1 cooling system lines are key in maintaining a steady flow of coolant through these parts.

The radiator is central to heat dissipation, transferring excess engine heat to the outside air. Coolant passes through the radiator, cools, and is cycled back into the engine via the 192-97 LT1 cooling system lines.

When the engine heats up, the thermostat opens to allow coolant to flow through the 192-97 LT1 cooling system lines.

The water pump is responsible for circulating coolant, working alongside the cooling lines to ensure smooth operation. Without it, overheating becomes inevitable.

Key Components:

- Radiator: Cools the circulating fluid.

- Thermostat: Controls flow based on temperature.

- Water Pump: Circulates coolant through lines.

How the 192-97 LT1 Cooling System Lines Enhance Engine Efficiency

The 192-97 LT1 cooling system lines are crucial for engine efficiency, as they help maintain optimal operating temperatures. This prevents excessive fuel consumption and keeps performance consistent.

As coolant flows through the lines, it absorbs heat from the engine, carrying it to the radiator for release. This process avoids overheating, which can otherwise lead to engine strain or damage.

Properly functioning 192-97 LT1 cooling system lines reduce friction within engine components, as ideal temperatures minimize wear and tear.

Efficient cooling also extends the lifespan of engine parts, helping vehicle owners avoid costly repairs or replacements. The right cooling line setup maximizes the overall engine output.

Enhanced efficiency is especially noticeable in high-performance driving, where cooling demands are higher. The 192-97 LT1 cooling system lines play a pivotal role in supporting this need.

Common Issues with 192-97 LT1 Cooling System Lines and Solutions

Over time, 192-97 LT1 cooling system lines may experience common issues such as leaks, blockages, or corrosion. Recognizing these problems early can prevent larger engine complications.

Leaks are often caused by cracks or wear in the lines, which disrupt the coolant flow and can lead to overheating. Regular inspections can identify leaks, and damaged lines should be replaced immediately.

Blockages can occur due to debris or coolant sediment buildup in the 192-97 LT1 cooling system lines. Flushing the system regularly helps maintain smooth coolant flow.

Corrosion is another common problem, often resulting from old or degraded coolant. Using high-quality coolant and performing system flushes can prevent this issue.

Solutions:

- Check for leaks regularly to prevent coolant loss.

- Flush the system periodically to clear blockages.

- Replace coolant to avoid corrosion-related damage.

LT1 Engine: Importance of a Proper Cooling System

A well-maintained cooling system is essential for the LT1 engine’s longevity and reliability. The 192-97 LT1 cooling system lines are a core part of this system, ensuring that heat is effectively managed.

With an efficient cooling system, the LT1 engine can perform under intense conditions without risk of overheating. Proper coolant flow maintains an optimal temperature range, which is crucial for engine health.

Excessive engine heat can lead to significant damage, affecting everything from gasket seals to pistons. The 192-97 LT1 cooling system lines play a preventative role by ensuring stable temperature control.

A reliable cooling system also improves fuel efficiency, as the engine doesn’t need to work harder to offset the effects of heat. This translates into both performance and cost benefits for the driver.

In addition to preventing overheating, the 192-97 LT1 cooling system lines help avoid pressure build-up, which can strain engine components. A balanced cooling system is therefore essential for maintaining the LT1’s power and resilience.

LT1 Engine: Importance of a Proper Cooling System

A properly functioning cooling system is crucial for the LT1 engine to perform at its best. The 192-97 LT1 cooling system lines play a key role in maintaining ideal engine temperatures, especially under demanding driving conditions.

When the cooling system is well-maintained, it prevents the engine from overheating, which can lead to severe damage and costly repairs. The cooling lines ensure that heat is constantly removed from critical engine areas.

The LT1 engine, known for its power, generates substantial heat. The 192-97 LT1 cooling system lines ensure this heat is effectively managed, allowing the engine to sustain peak performance.

A well-balanced cooling system also improves fuel efficiency. When the engine runs within its optimal temperature range, it consumes less fuel, saving the driver money and boosting performance.

Beyond performance, the 192-97 LT1 cooling system lines help to protect the engine’s components, such as gaskets and seals, from premature wear caused by excessive heat and pressure.

Importance of a Proper Cooling System:

- Prevents overheating and reduces the risk of costly repairs.

- Enhances fuel efficiency by maintaining optimal engine temperatures.

- Protects engine components from heat-related wear and tear.

Maintenance Tips for Extending the Life of LT1 Cooling System Lines

Regular maintenance of the 192-97 LT1 cooling system lines can significantly extend their lifespan and, in turn, the engine’s longevity. Simple but consistent upkeep can prevent many issues.

Inspecting the cooling lines for any visible cracks or signs of wear is essential. Early detection of such issues can save you from costly replacements or repairs down the line.

Flushing the cooling system periodically helps clear out sediment and debris that can clog the 192-97 LT1 cooling system lines. This keeps the coolant flowing smoothly and reduces the risk of blockages.

Ensuring that high-quality coolant is used and replaced regularly will prevent corrosion inside the lines. Corrosion can severely weaken the cooling system and reduce its efficiency.

Maintaining a proper coolant-to-water ratio is also important. This helps prevent freezing or boiling in extreme temperatures, which could strain or damage the 192-97 LT1 cooling system lines.

Maintenance Tips:

- Inspect lines regularly for signs of wear or damage.

- Flush the system periodically to remove debris and prevent clogs.

- Use high-quality coolant and maintain the correct coolant-to-water ratio.

Diagnosing Problems in the 192-97 LT1 Cooling System Lines

Diagnosing issues within the 192-97 LT1 cooling system lines early can save the engine from severe damage. Detecting problems often involves looking for specific symptoms and performing basic tests.

One common sign of a problem is engine overheating, which often results from blockages or leaks in the cooling lines. Checking for leaks visually or with pressure tests can help identify such issues quickly.

If you notice that coolant levels are dropping rapidly, there might be a leak in the 192-97 LT1 cooling system lines. Low coolant without visible leaks could indicate internal leakage or damage within the cooling system.

Blocked lines can restrict coolant flow, causing engine temperatures to spike. A quick diagnostic test, such as a coolant flow test, can confirm if there’s a blockage in the lines.

Squealing noises or poor engine performance may also indicate a cooling system issue. These symptoms suggest that the cooling lines or other parts, like the water pump, may be failing.

To ensure accurate diagnosis, regularly inspect the 192-97 LT1 cooling system lines and consider a mechanic’s assistance for more detailed tests.

Essential Upgrades for LT1 Cooling Systems

Upgrading the LT1 cooling system can enhance engine performance and durability. Adding high-quality 192-97 LT1 cooling system lines is one such upgrade, providing improved resistance to heat and wear.

Enhanced cooling lines designed for higher pressure can improve coolant flow and withstand more extreme conditions. This upgrade is beneficial for drivers who push their engines harder.

Switching to a larger or performance-grade radiator increases the cooling capacity, allowing the LT1 engine to operate more efficiently under stress. This helps prevent overheating in demanding driving situations.

Thermostats with adjustable settings are another essential upgrade. They provide better temperature control, especially when paired with high-quality 192-97 LT1 cooling system lines, ensuring the engine runs optimally.

Electric water pumps are another popular upgrade, offering consistent coolant flow and reducing the strain on the engine. These pumps can improve cooling efficiency and extend the life of the system.

Benefits of Upgrading:

- Improved coolant flow through durable, high-performance lines.

- Better temperature control with adjustable thermostats.

- Increased cooling capacity for high-performance demands.

How to Replace 192-97 LT1 Cooling System Lines: Step-by-Step Guide

Replacing 192-97 LT1 cooling system lines is straightforward but requires precision to ensure a secure installation. This guide provides step-by-step instructions for a safe replacement.

First, drain the coolant from the system to prevent spillage and allow for clean handling of the cooling lines.

Once drained, locate the 192-97 LT1 cooling system lines and detach any clamps or connectors securing them to the engine and radiator. Use pliers or a wrench to loosen these connections carefully.

Remove the old lines and inspect the surrounding area for any signs of wear or corrosion. Clean the fittings thoroughly to ensure a tight seal with the new lines.

Install the new 192-97 LT1 cooling system lines by securing them in place with clamps, ensuring there are no leaks or weak points. Refill the coolant reservoir with the appropriate coolant mix.

After installation, start the engine and monitor the lines for any signs of leaks. This final check ensures everything is functioning correctly.

Signs of Wear in LT1 Cooling System Components

Identifying signs of wear in the LT1 cooling system is crucial for avoiding potential breakdowns. Components like the 192-97 LT1 cooling system lines can show signs of aging that need immediate attention.

One common sign of wear is visible cracks or brittleness in the cooling lines. These can lead to leaks and reduced coolant flow, risking engine overheating.

Discoloration or rust on the cooling lines may also indicate corrosion, especially if the coolant hasn’t been replaced regularly. Corrosion weakens the lines, making them prone to leakage.

Bulging in certain sections of the 192-97 LT1 cooling system lines suggests pressure build-up or a potential blockage. This is a serious issue that requires immediate inspection and replacement if needed.

If the engine consistently runs hotter than usual, it could indicate worn-out cooling system components or leaks within the system.

Finally, frequent coolant loss without an obvious leak could mean internal wear in the cooling system lines, leading to hidden coolant escape routes.

Cooling System Line Types: Choosing the Best for LT1 Engines

Choosing the right cooling system lines for the LT1 engine ensures reliable performance and durability. The 192-97 LT1 cooling system lines are specifically designed for this engine but come in various materials and types.

Rubber lines are a common choice due to their flexibility and affordability. However, they may wear out faster than other materials, especially in high-temperature environments.

Silicone cooling lines offer higher heat resistance and durability, making them a popular option for LT1 engines used in performance settings. They withstand extreme conditions better than rubber lines.

Braided stainless steel lines provide additional protection from abrasion and extreme temperatures, making them ideal for drivers seeking maximum durability and longevity for the 192-97 LT1 cooling system lines.

When selecting a cooling line type, consider the climate and driving style. High-performance or high-temperature conditions may require upgraded materials like silicone or braided stainless steel.

Types to Consider:

- Rubber lines: Affordable and flexible but may wear out faster.

- Silicone lines: High heat resistance for performance engines.

- Braided stainless steel lines: Best for maximum durability and protection.

Troubleshooting LT1 Cooling System Overheating

Overheating in the LT1 cooling system can be due to various factors, with the 192-97 LT1 cooling system lines often playing a role. Diagnosing and resolving the issue quickly can prevent serious engine damage.

Check the coolant level first, as low coolant is a common cause of overheating. If the level is low, inspect the cooling lines for leaks or visible damage.

Blocked or restricted 192-97 LT1 cooling system lines can prevent coolant from circulating properly, leading to overheating. Flush the system to clear out any debris or sediment that may be causing a blockage.

If the water pump is not functioning correctly, it can disrupt coolant flow, causing the engine to overheat. Ensure that the pump is operating smoothly and without obstruction.

A malfunctioning thermostat can also cause overheating by restricting coolant flow. If the thermostat isn’t opening as needed, replace it to restore proper cooling.

Regularly inspect the cooling system lines, as even minor leaks can contribute to overheating over time. Replacing damaged 192-97 LT1 cooling system lines is a preventive measure against future issues.

Tools and Equipment for Working on LT1 Cooling Systems

Having the right tools and equipment is essential when working on 192-97 LT1 cooling system lines or other cooling components.

Pliers and hose clamp tools are essential for loosening and securing the cooling lines. These tools help avoid damaging the clamps and ensure a tight fit.

A coolant drain pan is necessary for collecting old coolant safely. This prevents spillage and allows for proper disposal of used coolant, keeping the workspace clean.

Wrenches and screwdrivers are often required to remove and replace bolts, hoses, or clamps on the 192-97 LT1 cooling system lines. A complete set of these tools is ideal for a smooth repair process.

A coolant funnel and refill kit make it easier to add coolant back into the system after repairs or replacements. This setup helps avoid air pockets that could compromise cooling performance.

Finally, a pressure tester can be useful to check for leaks after installation. It allows you to monitor pressure levels and ensure that all connections are secure.

Essential Tools:

- Pliers and hose clamp tools for secure line installation.

- Coolant drain pan to catch and dispose of old coolant.

- Pressure tester to check for leaks and maintain system integrity.

Conclusion

Maintaining and upgrading the 192-97 LT1 cooling system lines is essential for preserving the performance and longevity of the LT1 engine. These cooling lines play a crucial role in regulating engine temperature, reducing the risk of overheating, and ensuring efficient operation under various conditions.

Regular inspections, proper maintenance, and timely replacements are key to avoiding common issues like leaks, blockages, or corrosion in the cooling system. By investing in quality components and following a consistent maintenance routine, LT1 engine owners can prevent costly repairs and keep their engine running smoothly.

Upgrading to high-performance cooling lines or components is especially beneficial for those who push their engines to higher limits. Enhanced cooling lines, thermostats, and pumps can improve both efficiency and durability, supporting the engine’s peak performance.

In sum, the 192-97 LT1 cooling system lines are a fundamental part of the engine’s health. With proactive care, LT1 owners can maximize their vehicle’s reliability and power, ensuring it withstands demanding conditions for years to come.